THE FELT INNOVATOR

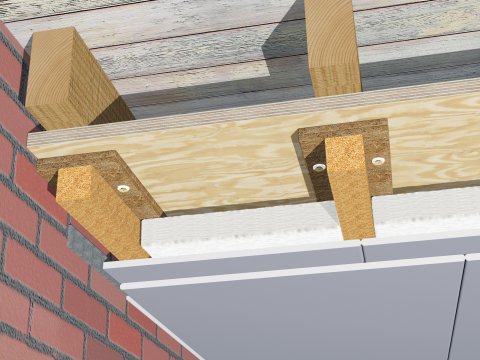

The sound insulation of a structure can be improved by means of a properly designed "flexible" dry lining wall, "floating" floor, "suspended" ceilings, or a "floating" roof. And these structures can be easily created thanks to the IVI-Soundbatten timber frame system.

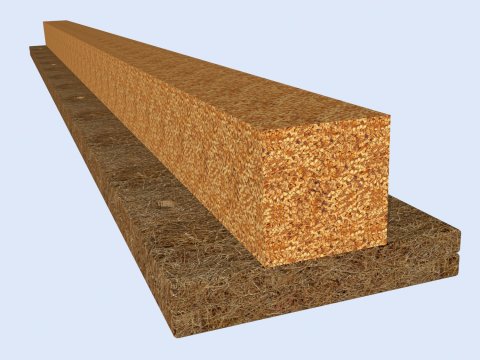

The IVI-Soundbatten consists of a permanent, flexible strip, to which a batten of water-resistant chipboard is adhesively bonded. The IVI-Soundbatten system creates a resilient timber frame structure, on which a final cladding is applied, consisting, for example, gypsum plasterboard, gypsum fibreboard, or cement bonded board. These boards bring the important factor of mass into play.

The sound insulating properties of a dry lining structure depend on two factors. The principle which applies is that the greater the cavity, the better the effect. Nevima accordingly provides battens in three thicknesses (40, 60 and 80 mm), which have the effect of creating cavities of the same depths. In addition to this, a greater cladding mass results in a better effect; Nevima accordingly recommends the application of an offset double cladding.

IVI-Soundbatten ceiling

IVI-Soundbattens have been used with great success for years, for example for the damping of noise from the surrounding environment, in the catering sector, and for reducing aircraft and traffic noise. The connection between the felt and the batten is ensured by mechanical means.

INSTALLATION

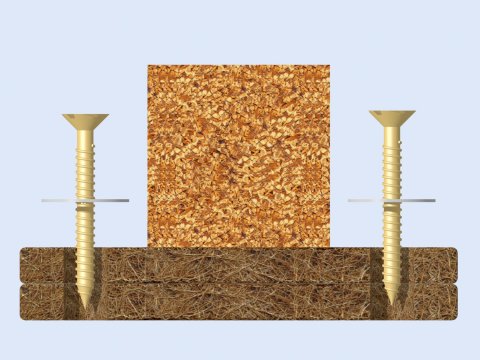

The Installation of the resilient dry lining structure with the IVI-Soundbatten is easy. First of all, any gaps or cracks in the existing structure must be sealed up. Self-adhesive Nevima IVI-Acoustic band is applied to the structural elements to where the cladding material will be joined. Next, the battens are secured, using nailable plugs or woodscrews with shims, depending on the substrate. To help achieve this, pre-punched holes are provided in the flexible strip. If the IVI-Soundbatten is being used on the floor, the battens especially designed for this application are laid loose on the floor.

Vibrations which may nevertheless be taken up through the cladding, are damped by the resilient battens, which means they cannot pass through as far as the existing structure.

In order to avoid what is referred to as the resonance body effect, a sound-absorbing material such as rock wool or glass wool is inserted between the battens; this material must fill at least 70 % of the cavity depth.

Final processing

Once the cladding material has been fitted, the seams are sealed with a flexible sealant at the height of the acoustic band. If there are more stringent demands being placed on the structure with regard to fire resistance, a sealant must be used which is especially intended for this purpose.

The dry lining structure created using the IVI-Soundbatten is designed to be able to hold those objects which would normally be secured to a wall or ceiling. In situations in which heavier objects must be attached, additional IVI-Soundbatten elements can be fitted at the securing point.

The procedure instructions provided with the material describe step by step how the sound-proofing structure is to be created.

Composition of a resilient dry lining with the IVI-Soundbatten

A complete dry lining structure using the IVI-Soundbatten consists of the following components:

- Nevima IVI-Acoustic band *¹)

- Nevima IVI-Soundbatten

- Nevima nailable plugs or woodscrews with shims *²)

- Absorption material

- Cladding material

- Drywall screws

- Acrylic sealant

*¹ ) The Nevima IVI-Acoustic band consists of 100 % recycling polyester fibres, and is supplied on rolls of 10 m in length, in a thickness of 5 mm and a width of 32 or 42 mm.

*²) Nevima nailable plugs with shims are supplied in cartons of 100 units, in the dimensions of 6 mm diameter and 60 mm length. Nevima woodscrews are supplied in cartons of 200 units.

Dealers

| Company | PO code | City | Phone |

|---|---|---|---|

| BMN groep | Alle vestigingen | ||

| Raab Karcher | Alle vestigingen | ||

| 4PLUS Bouwmaterialen | Alle vestigingen | ||

| Keulen Hout - en Bouwmat., van | 1033 SG | Amsterdam-Noord | 020 - 4604300 |

| Goedkoop Bouwmaterialen | 1115 AC | Duivendrecht | 020 - 6982221 |

| Pontmeyer | 1332 AK | Almere | 036 - 5328092 |

| Carpentier Bouwproducten | 1432 AG | Aalsmeer | 0297 - 380610 |

| Pontmeyer | 1506 RZ | Zaandam | 075 - 6536262 |

| Baustoff + Metall B.V. | 2371 DZ | Roelofarendsveen | 071-7517751 |

| Tol, van | 2461 EZ | Ter Aar | 0172 - 603642 |

| Pontmeyer | 2516 BB | Den Haag | 070 - 3838700 |

| Goedkoop Bouwmaterialen | 2629 HG | Delft | 015 - 2616126 |

| Verdouw Gouda | 2806 CG | Gouda | 0182 - 597300 |

| Wijngaarden en Co, van | 3087 AH | Rotterdam | 010 - 4281444 |

| Jongeneel (NL) | 3542 AB | Utrecht | 030 - 2346347 |

| De Jager-Tolhoek | 4462 GL | Goes | 0113-246690 |

| Jongeneel | 4531 BW | Terneuzen | 0115 - 613655 |

| Pontmeyer | 5015 AK | Tilburg | 013 - 4620200 |

| SIG Logistics | 5145 PD | Waalwijk | 013 - 5498680 |

| Baustoff + Metall B.V. | 5222 AM | Den Bosch | 073-6270560 |

| Pontmeyer | 5692 HE | Son | 0499 - 477144 |

| Jongeneel | 5928 PB | Venlo | 077 - 3241080 |

| Thiessens BV | 6229 PM | Maastricht | 043 - 3610580 |

| Pontmeyer | 7418 CG | Deventer | 0570 - 623960 |

| Astrimex B.V. | 9351 NP | Leek | 0594 - 552323 |

| Liparos | B 9620 | Zottegem | +32 9 3601254 |

| Akoestix Products | B-8020 | Oostkamp | +32 50547428 |

| M. Rieke GmbH & Co KG | D-49509 | Recke | +49 5453 93320 |